Pure Air Design's 3 Step Process

Step One

Pure Air Design’s process is designed to thoroughly sterilize and decontaminate, before installing preventive measures designed to make your home, business, and outdoor workspaces as safe as possible. Our process is the Solution for destroying Viruses, Bacteria, Mold, and Spores, by implementing Medical Grade EPA and OSHA Approved Guidelines, Equipment, and Procedures. Our process starts with Sterilization and Decontamination, utilizing Electrostatic Cleaning Equipment that targets and destroys 99.9% of Viruses, Bacteria, Mold, and Spores.

Next, we use an EPA Registered Anabec Anasphere Disinfectant spray, which also targets and destroys 99.9% of Viruses, Bacteria, Mold, and Spores. Covering all the accessible areas of your home or office in an overlapping pattern with the Electrostatic Disinfecting Cleaning Equipment, this technique helps to ensure the best coverage of the sterilization steps.

Further decontamination is then (run) implemented with our custom UV-C Medical Grade Decontamination Appliances, which target and destroy 99.9% of Viruses, Bacteria, Mold, and Spores. These Medical Grade Decontamination Appliances are installed with timers and motion sensors to provide overlapping coverage, further eliminating any traces of viruses, bacteria, mold, or spores, day and night. Pure Air Design’s experts work with your schedule to utilize these Decontamination Units, during low traffic times, following rigorous protocols and safety standards.

Further decontamination is then run with UV-C Medical Grade Decontamination Units, which target and destroy 99.9% of Viruses, Bacteria, Mold, and Spores. These Medical Grade Decontamination units are run on timers, at night, to further eliminate any traces of virus, bacteria or mold, while also ensuring safety standards are met. These Decontamination Appliances emit high range UV-C light waves which require our Experts to follow Medical Grade Protocols. Pure Air Design’s Experts take precautions, scheduling with you a time of low to no traffic at your home or business.

Step Two

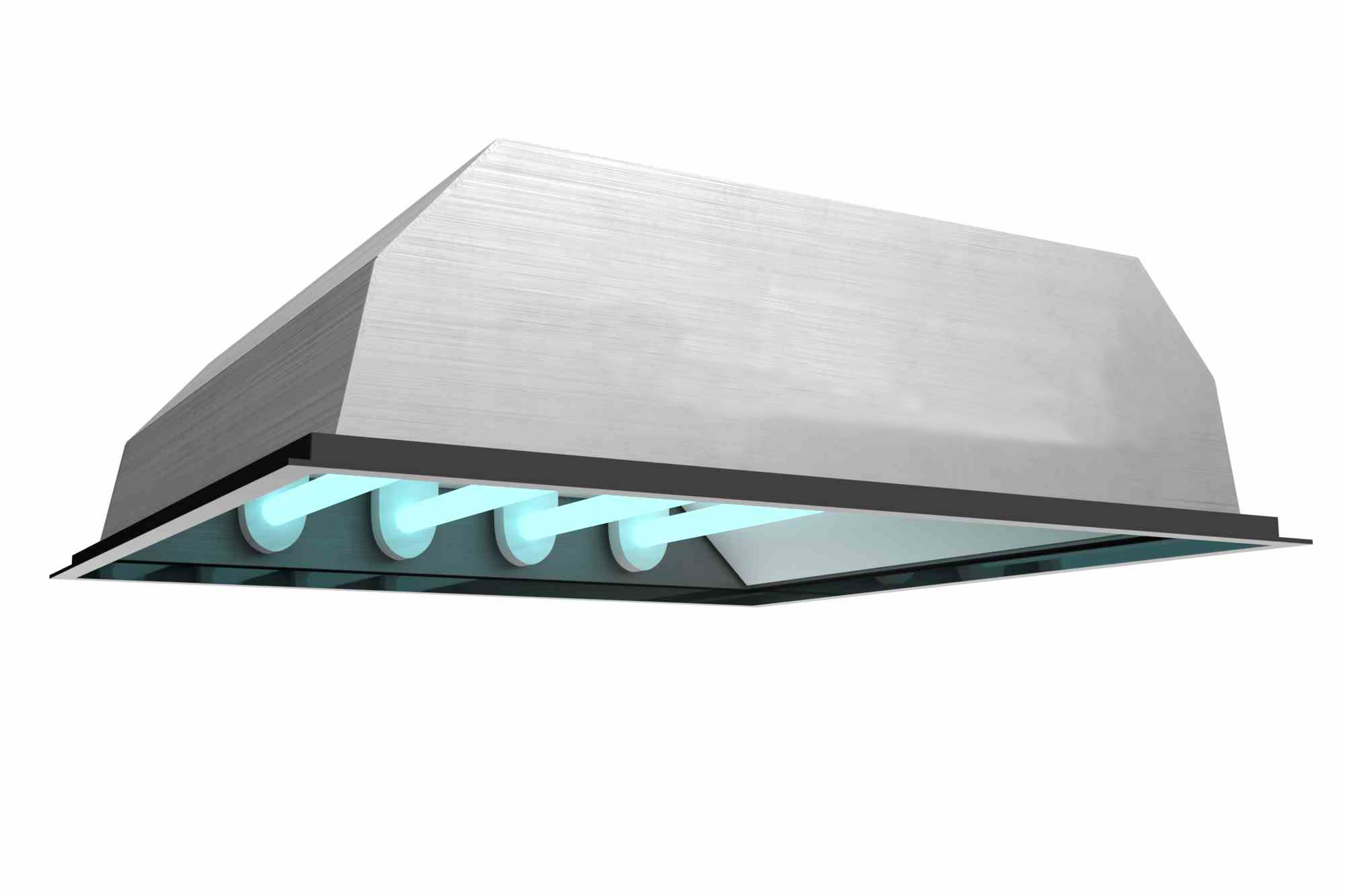

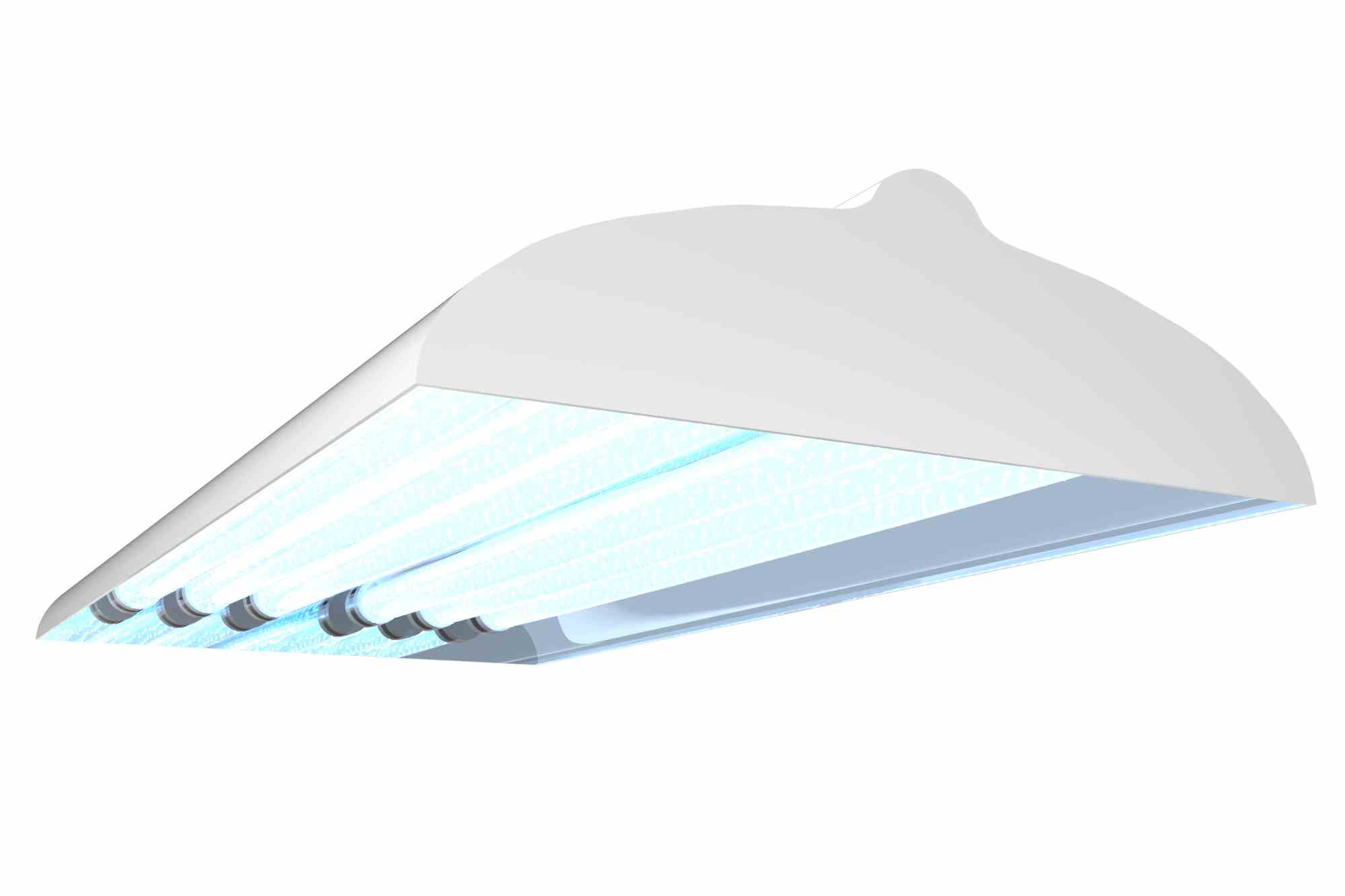

Pure Air Design cleans, modifies, and installs UV-C Germicidal Lighting Fixtures, which target and destroy 99.9% of: Viruses, Bacteria, Mold, and Spores, as well as UV-C Far Germicidal Lighting. UV Light and its properties contribute to sanitation and disinfection and can be used to fight against Viruses, Bacteria, Mold, and Spores. According to data collect by the International Ultraviolet Association (IUVA), UV treatment has been in use for more than 40 years. Mostly used in enclosed and protected systems, notably in Hospitals, Medical Clinics, Laboratories, Food Processing, and Water Treatment Plants. These in use cases reinforce the benefits of utilizing UV light to eliminate Coronavirus and Covid-19.

A common use of UV-C Lighting is in Autoclaves, curing stations, and other enclosed cleansing systems. These systems are used for sterilizing and curing Medical Equipment and Electronic Devices. Like: Cell Phones, Tablets, gaming devices, and other remote controls.

Step Three

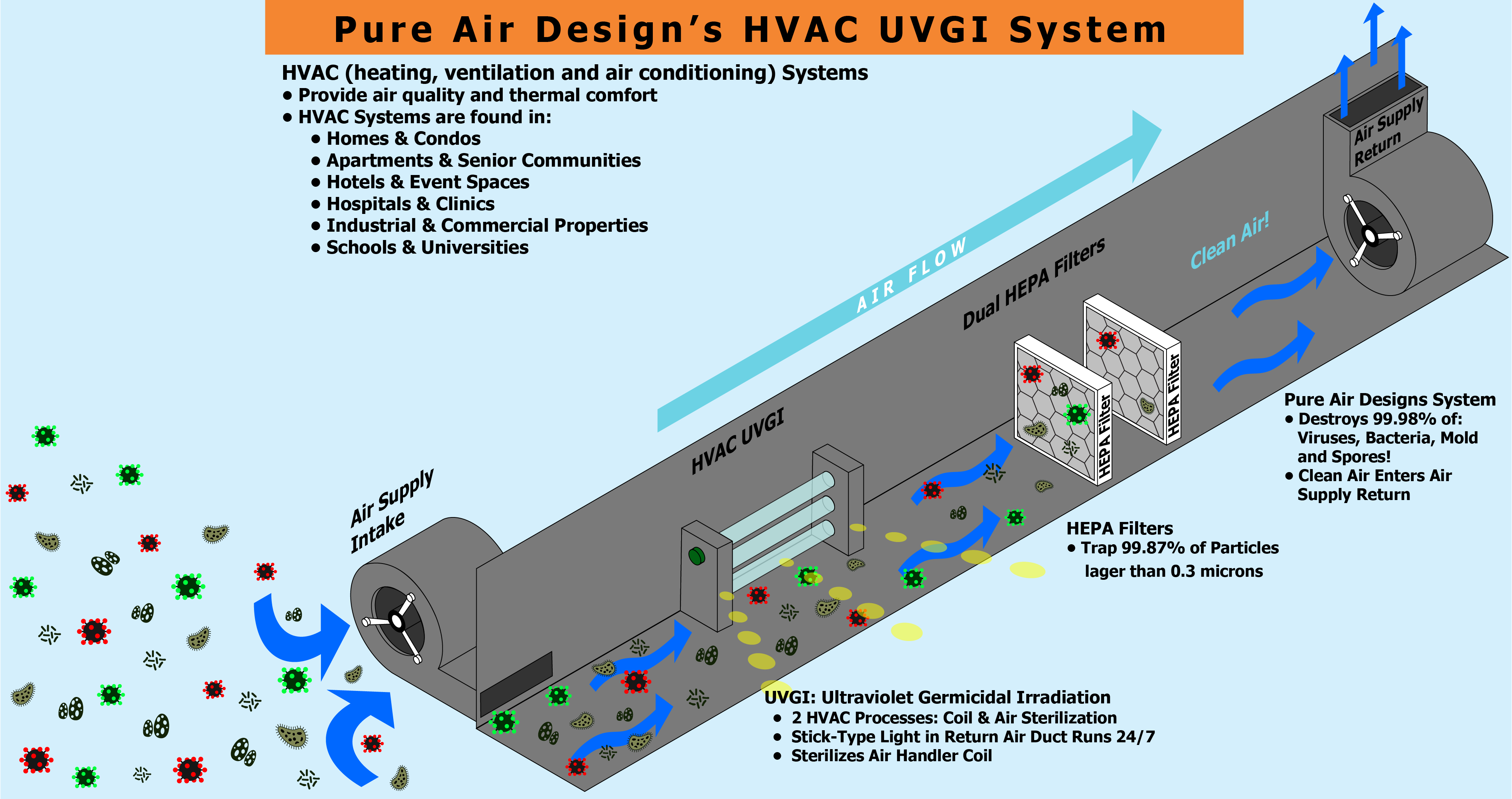

HVAC Air Duct UV-C Light Systems. These contained UVGI systems target and destroys 99.9% of: Viruses, Bacteria, Mold and Spores.

Killing viruses and bacteria at the source or before they spread as inhalants or come into physical contact with humans is the best way to mitigate their spread and stop infections. HVAC systems (heating, ventilation and air conditioning systems) provide acceptable air quality and thermal comfort, while maintaining a controlled and enclosed system. HVAC systems are found in single-family homes, apartment buildings and condominiums, hotels, senior living facilities, hospitals, industrial facilities, schools and universities, office buildings and more. Given their broad use of these systems and how many people around the world rely on them for clear and breathable air it makes sense that UV light would be used inside the system to kill bacteria and viruses to make the air as clean as possible.

The type of UV light used inside HVAC systems is called UVGI (Ultraviolet Germicidal Irradiation), and can be used in two internal HVAC processes: coil sterilization and air sterilization. Coil sterilization is the most common type of HVAC UV light method because it can run 24 hours a day, seven days a week to ensure maximum sterilization. This type of application, “a ‘stick-type’ light is installed inside the return air duct and it sterilizes the air handler coil. On an HVAC system the coil and drain pan are typically the places where contaminants such as viruses and bacteria can originate. By adding a UV light to the coil, the origin of the contamination is treated before any bacteria, virus or mold spores are able to become airborne and contaminate the air.

In the air sterilization method a UV light is installed in the return air duct and cycles on with the air handler blower the unit sterilizes moving air itself as it is pushed through the HVAC system. With this method, the air is already assumed to be or is contaminated and is itself treated, as opposed to treating the coil before the contamination makes it into the air as with the previous coil sterilization method. This method requires the UV light too only turn on when the heating or cooling system is running.

The use of UVGI light inside HVAC systems can be extremely effective in purifying and sterilizing the air inside homes, commercial buildings and industrial facilities to help mitigate the spread of airborne pathogens. UV light has been found to be a very effective method in killing viruses and bacteria if used properly and within the germicidal wavelengths. With proper installation the Estimated Regulation (CFM) on 1500 a 1500 Square Foot space is a complete air cycle through the system in 3-4 minutes.

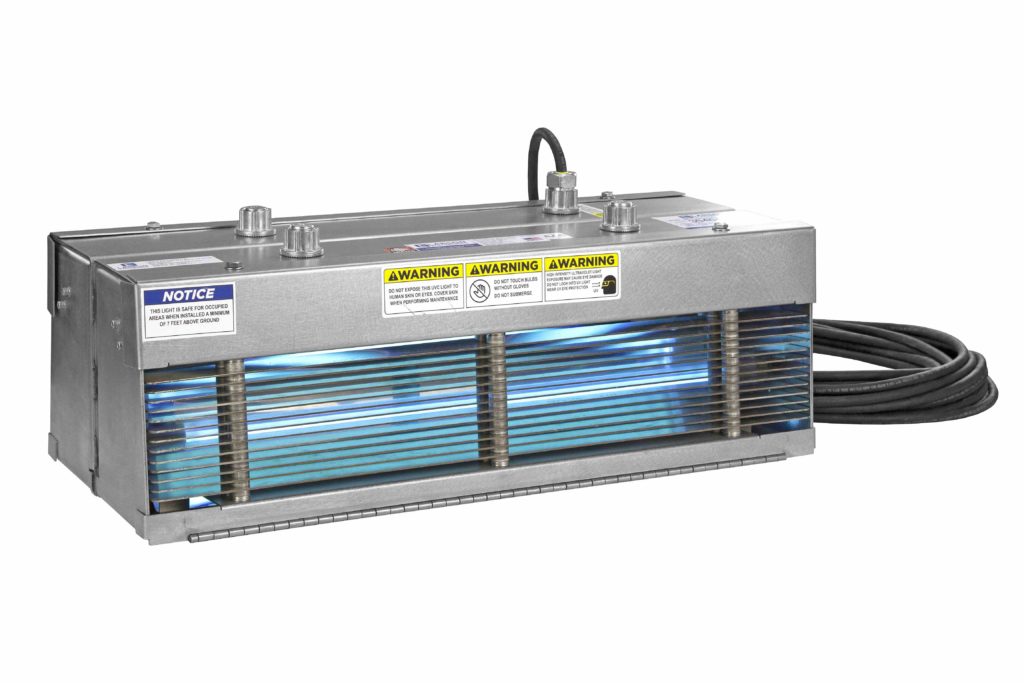

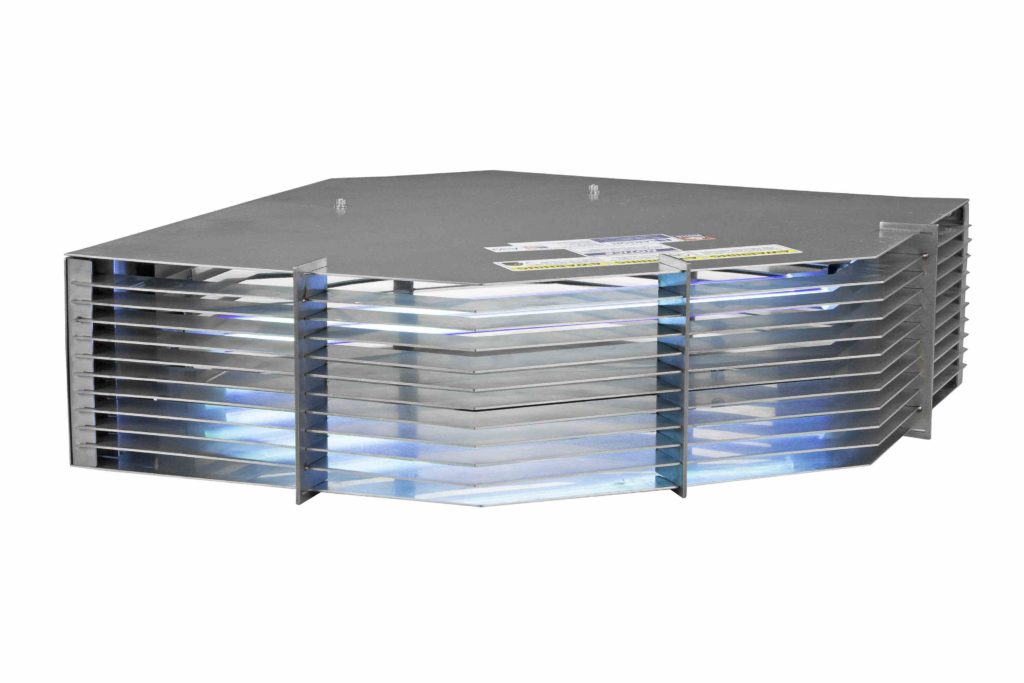

HVAC UVGI INSTALLATION

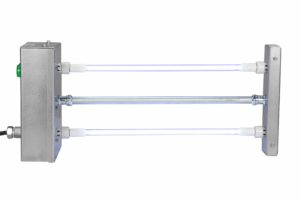

Wall Mounted Disinfection Appliances.

These are powerful sanitation solutions for industrial sites and commercial facilities. The air passing through this UV-C System is Disinfected destroying 99% of Viruses, Bacteria, Mold, and Spores. The site is constantly being purified as the air flows through the UV-C System via convection currents and forced air circulation.

UV-C LIGHTING

UV-C FAR

Understanding UV-C and UV-C Far Technology

UV light contains several unique properties and characteristics, these can be used to disinfect viruses, bacteria, mold, spores, and other harmful microbes. This sanitation method relies on

UV-C wavelengths (UV bands within the 200nm to 280nm range) to deactivate the cellular ribonucleic acid (RNA) and deoxyribonucleic acid (DNA), as well as the reproductive capabilities

of microorganisms.

With the spread of Coronavirus 2019 (COVID-19 or SARS-CoV-2), there has been a surge in the use of UV light to sanitize buildings, work sites, equipment, respirator masks, and patient rooms. UV treatment is confirmed to eliminate COVID-19 by Juan Leon, an environmental health scientist at Emory University. Through published studies and documentation, researchers have verified UV-C sanitation to deactivate previous strains of the Coronavirus, such as Severe Acute Respiratory Syndrome (SARS-CoV) with the first human case appearing as far back as 2002 and Middle East Respiratory Syndrome (MERS-CoV) with the first human case appearing as far back as 2012. During the spread of SARS-CoV and MERS-CoV (respectively), UV light disinfection played a vital role in preventing the spread of disease.

In addition to coronavirus, UV light is used to deactivate other types of harmful disease-causing microbes. According to experts from the University of British Columbia, University of Alberta,

The University of Colorado-Boulder and Trojan Technologies, UV-C light is capable of killing: tuberculosis, e.coli, methicillin-resistant S. aureus (MRSA), and more. This form of sanitation also

targets mold, spores, fungi, and yeast.

It is important to understand the differences between UV-C and UV-C Far Technologies. These factors must be taken into consideration when administering UV-C light to eliminate viruses or bacteria in the area. These factors include: light intensity, duration of treatment, the distance between the UV light source and object or surface, obstructions, and environment (temperature and humidity). To ensure effective UV disinfection, different types of UV-C devices can be utilized. UV-C light is harmful to humans as it can cause burns on the skin and damage the cornea.

Far-UV 222 nm light contains effective germicidal properties that are significantly safer to humans, compared to other penetrative UV wavelengths, as the bands are not cytotoxic or

mutagenic to mammalian cells. A 2017 study highlights the level of safety at 222nm, authors of the study cited that far-UV light cannot penetrate the stratum corneum of the skin, thus

protecting foundational basal cells from damage. This specific UV band cannot penetrate the thick barrier protecting the cornea. Far-UV 222 nm is considered to be safe on human

eyes, as suggested by the researchers of the study.

By comparison, UV rays in the 254 nm spectrum can cause skin and eye damage skin. The germicidal effectiveness and capabilities of far-UV 222nm are very similar to conventional UV-C 254nm, as both UV bands fall within the UV-C range of 200nm to 280nm.

UV-C Germicidal Lighting is suggested for use in control environments and systems. Such As: Autoclaves, HVAC Systems, Medical Exam Rooms (When paired with Senors and Timers), in Portable and Handheld Equipment used by RCD during clean-up and installation, and other contained and monitored systems.

UV-C Far Lighting is safe to use in a wider range of places as sustainable light solutions. Such As: Clinic Waiting Rooms, Business Offices, Warehouses, Shopping Centers, Gyms, Class Rooms, and other places where traditional Fluorescent lighting would be used.